This 3D-Printed Robot Has Tendons, Ligaments, And „Bones” – Just Like A Human Hand

New printing technology means different materials can be combined like never before.

The latest advances in 3D printing have been put to good use by scientists at ETH Zürich, who have now unveiled an incredibly human-like robotic hand. What makes this hand unique is that it’s made up of bones, ligaments, and tendons – all the building blocks of a human skeleton – created from different flexible polymers, opening up a whole world of potential applications for this technology.

Not so long ago, we would have been hard-pressed to imagine a world where people could have 3D printers inside their own homes – but now that sci-fi fantasy has become a reality. The development of this technology has accelerated massively in recent years; people have printed everything, from cakes and vegan fish substitutes to medical devices and even a rocket.

Initially, the materials that could be used for 3D printing were limited to fast-curing plastics, but new methods developed by researchers at ETH Zürich in collaboration with US-based startup Inkbit have broadened this to include slow-curing plastics as well. Now, it’s possible to print objects containing multiple materials at once, and to combine soft, elastic, and rigid materials into more complex shapes than ever before.

“We wouldn’t have been able to make this hand with the fast-curing polyacrylates we’ve been using in 3D printing so far,” explained the study’s first author Thomas Buchner in a statement. “We’re now using slow-curing thiolene polymers. These have very good elastic properties and return to their original state much faster after bending than polyacrylates.”

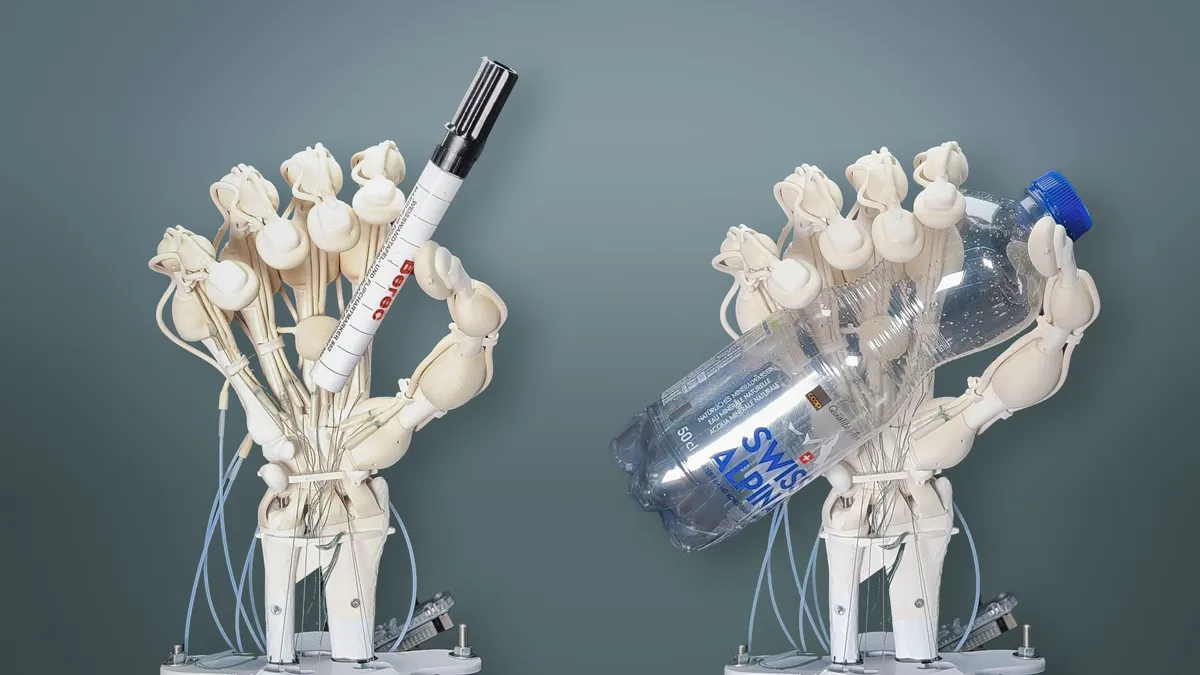

Normal 3D printing works by building up the shape in layers. A UV lamp is used to cure the plastic in between each layer, and a scraper smooths out any irregularities on the surface before the next layer is put down. That doesn’t work with slow-curing plastics, however, because they would remain too sticky and clog up the scraper.

The team got around this by using lasers to perform a 3D scan of each layer. Where there are irregularities, the machine can recalibrate to ensure that the next layer takes these into account, so there’s no need to scrape the surface smooth each time.

“A feedback mechanism compensates for these irregularities when printing the next layer by calculating any necessary adjustments to the amount of material to be printed in real time and with pinpoint accuracy,” said study co-author Professor Wojciech Matusik of MIT, where Inkbit is based. Having now perfected this technique, they plan to continue to explore its applications as well as offer this new service to Inkbit’s customers.

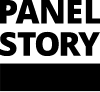

When it comes to the robotic hand, its unique construction offers several advantages, as senior author Professor Robert Katzschmann explained: “Robots made of soft materials, such as the hand we developed, have advantages over conventional robots made of metal. Because they’re soft, there is less risk of injury when they work with humans, and they are better suited to handling fragile goods.”

Whether it’s bringing 450-million-year-old extinct organisms “back to life”, creating a smart glove that can learn to play piano, or building a wiggly escape artist that needs no help from humans, soft robotics is creating some of the most exciting advances in tech today – all of these examples are from this year alone. Now, thanks to these innovations in 3D printing, we can add a whole raft of new inventions to this list.

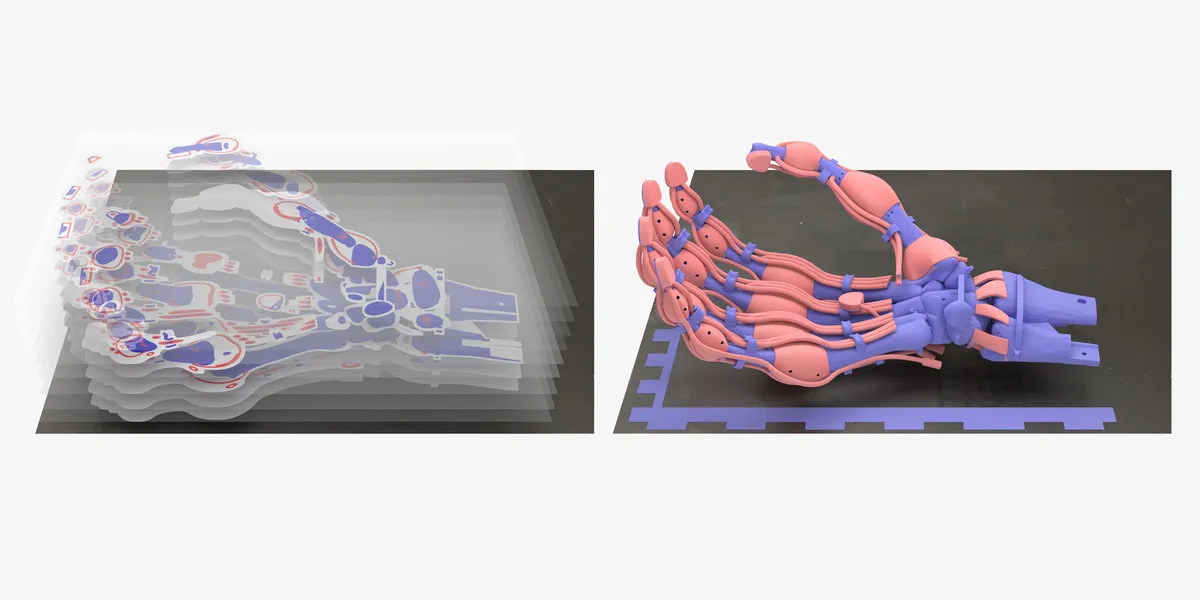

“We directly fabricated a wide range of complex high-resolution composite systems and robots: tendon-driven hands, pneumatically actuated walking manipulators, pumps that mimic a heart and metamaterial structures,” the authors wrote in their paper. And it doesn’t have to stop there.

“Our rapid and versatile manufacturing technology will create new opportunities for scientific investigations, experimental design, complex prototyping and industrial innovation.”

The study is published in the journal Nature.